1. High Control Precision

It supports 4-axis analog quantity, full closed-loop control, pulse direction, and EtherCAT bus control, adapting to different application scenarios. It can control stepping/servo/linear motors. The improved S-curve acceleration and deceleration algorithm and look-ahead control make the machine tool speed faster and more stable. It is designed for high-precision equipment and can achieve fast and good processing of small circles.

2. Fast Computing Speed

3. Ethernet Port Communication

It uses 100/1000M Ethernet for communication, which is fast and stable. There is no need to install driver programs. The control system operates independently and is not affected by industrial computer failures, making the operation of machine tool equipment systems more stable.

4. Large Data Storage Capacity

5. Provide a Complete Set of Mature Application Control Software

6. Other Features

Supports gantry dual drive.

Supports position comparison and triggering.

Supports pulse synchronous output (PSO), which can be used for energy control in the laser industry, improving cutting quality. It is very suitable for the control of automation equipment and has powerful online analysis and debugging software, making machine adjustment easy.

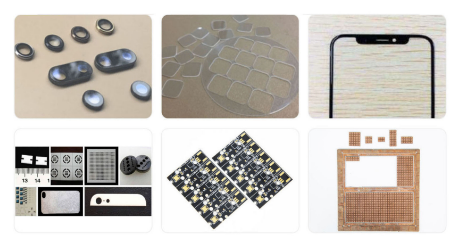

The QLC-420 and its supporting software are very suitable for automation equipment fields such as steel sheet/sheet metal cutting, ceramic/sapphire/glass cutting and slicing, wafer cutting and slicing, aluminum substrate cutting, large-area light guide plate marking, two-dimensional code detection, and printing machines.